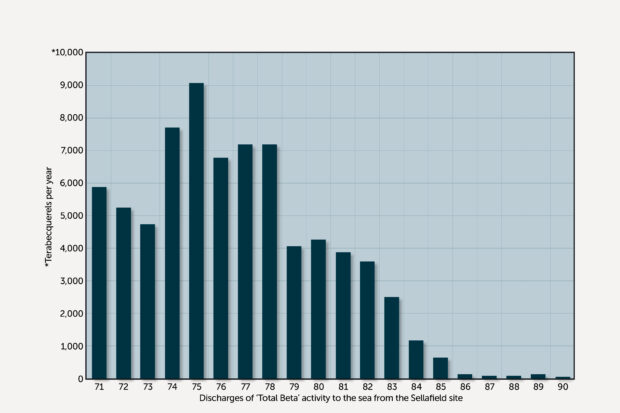

A quick glance at a chart that documents radioactive discharges from the Sellafield nuclear site into the sea tells you that something significant happened in 1985.

Almost overnight, the discharge of important radionuclides (caesium and strontium) dropped.

This wasn’t the result of closing nuclear facilities or stopping the electricity generation, used fuel reprocessing, and nuclear waste management work that was happening on the site at the time.

Instead, it was the immediate impact of a new building, the Sellafield Ion Exchange Effluent Plant, or SIXEP as it is known by the people working on site.

In its 40 years of operations, SIXEP has safely removed 99.9% of the radioactivity from 30 million cubic metres of water. To put that into context, that volume would supply enough water for every household in the UK for three days.

SIXEP was one of the first facilities I heard about when I joined the company 25 years ago. Can anything else that we do at Sellafield come close to this significant contribution to the protection of the environment? As I sit here now as head of environmental management, I like to think so.

What SIXEP teaches us is that people at Sellafield have always risen to the challenges set to them – in this case how can we capture radioactivity from water that’s been used in nuclear operations so that it isn’t discharged to sea?

Their achievement is a story of innovation, creativity, and a relentless commitment to improving environmental protection. It is also a story that features the unique properties of a natural resource from the Mojave Desert.

From California to Sellafield - how a natural mineral drives SIXEPs environmental performance

We use water in lots of our processes at Sellafield, including keeping used nuclear fuel cool in legacy and modern storage ponds.

As it meets radioactive material, it picks up radionuclides like Caesium and Strontium as well as small solid particles.

The water travels along the site via a network of pipes before ending up in SIXEP. Here it goes through 2 main processes.

First, it passes through a vessel containing a bed of sand which captures the small, solid particles. It then goes into a second vessel that contains a natural mineral called Clinoptilolite. It is this mineral that captures the caesium and strontium from the water.

Clinoptilolite is a natural zeolite and was mined in bulk from a specific area of the mud hills mine in the Mojave Desert, California back in the early 1980s.

We keep the used sand and Clinoptilolite (and the successfully captured radioactivity) from the SIXEP process on the site, and the now processed water is discharged to the Irish sea.

Learning from the past

SIXEP was under construction when, in 1983, an error meant that radioactive solvent and solids were discharged from our Magnox Reprocessing Plant into the sea. Weather and tidal conditions caused a slick to form and contaminated debris washed up on the beaches close to Sellafield.

No-one – not a member of the public or people working on the site at the time – received any radioactive dose as a result of the incident.

Our business – then called British Nuclear Fuels Ltd was prosecuted.

By this point SIXEP was fully operational, a positive legacy from what was a difficult chapter of the Sellafield story.

How do we know that SIXEP is working?

The water that we discharge from Sellafield is permitted by the Environment Agency.

As well as sampling the water before it is discharged, we’ve also got a comprehensive environmental monitoring programme that gives us confidence that SIXEP is doing its job and that the water discharged is within the permitted levels.

Our environmental monitoring programme (started in the 1950s) goes far beyond helping measure the performance of SIXEP and provides high confidence that impacts remain very low from all discharges from the site.

Our environmental monitoring is also backed-up by independent assessment, and findings are published every year on GOV.UK.

Beyond SIXEP

Our need for SIXEP will go on beyond the original design life of the plant. Which is why we’re currently building an extension. The SIXEP Continuity Plant is being build next door to the current SIXEP building and will ensure that we continue to treat the water we use in our processes for decades to come.

But we’re not just relying on SIXEP in our relentless pursuit of environmental protection. The world is changing around us, as are the environmental expectations of government, regulators and members of the public.

Forty years ago, eyes were on us reducing radioactivity in our discharges to sea, with SIXEP making a huge and lasting difference.

We still pay very close attention to minimising our radioactive discharges, now alongside other areas of increasing environmental focus, including reducing our carbon emissions, strengthening our resilience to a changing climate, minimising our demands on natural resources (including water); and the size and scale of our solid waste management challenges.

If I take carbon emissions reduction, and the government drive (legislation) for Net Zero (2050). When you consider the discharge graph from pre- and post-1985 and that rapid decrease in our radioactive discharges, there are direct parallels to our carbon emission reduction requirements. Around five years ago we started to seriously look at how to reduce our greenhouse gas emissions.

There is no SIXEP equivalent that we can bolt-on to the site, but we have already reduced emissions by around 40%. That is through a combination of changes in business operations and pursuit of alternative technologies to reduce reliance on fossil-fuelled power.

We still have a way to go but that same SIXEP spirit of innovation, creativity, and a relentless commitment, keeps us in the driving seat to improving environmental performance and protection.

Recent Comments