What do you know about Sellafield? Encircled by miles of fencing, and with armed guards at its gates, for many people - Sellafield is an enigma.

Sellafield itself is in north-west England, in a remote coastal location with the Irish Sea on one side and the mountains of the Lake District on the other.

Sellafield the town

Covering a footprint of 2 square miles, hundreds of buildings and thousands of people, Sellafield needs some of the same infrastructures as a small town.

Did you know that Sellafield has:

- an active and non-active laundry?

- a postal service?

- canteens?

- shops?

- utilities, including water and steam?

- a road and rail network?

- an armed police force?

- a civilian guard force?

- emergency services including fire and rescue and paramedics?

- a medical team?

Sellafield is changing

Here we’ll explain what Sellafield was when the site first opened, what it is today – and what it’s becoming.

The best of the best people work here, in a range of extraordinary roles. And we have a critical mission.

70 years of national service

In 1947, the Sellafield site opened with a single mission – the production of plutonium, a radioactive chemical element for use in Britain’s nuclear deterrent. As the nation’s priorities shifted, pioneers at the site:

- designed and built the world’s first commercial-sized nuclear power station

- recycled nuclear fuel so that both plutonium and uranium, another chemical element, could be recovered and reused

- created safe treatment and storage options for all types of nuclear waste

Today the Sellafield site presents one of the most significant environmental remediation challenges in Europe.

Did you know?

- Sellafield covers 2-square miles

- it operates 24-hours a day, 7 days a week, 365 days a year

- it’s home to 4 of the biggest nuclear risks and hazards in Europe

- over 10,000 staff operate the site

- more than 4,000 supply chain experts help our employees

- we spend £2 billion every year – but are a non-profit organisation

From farm to munitions

As far back as 1611, people have lived on the land on which Sellafield now sits. Originally, there were 7 tenant farms at High Sellafield and another 7 at Low Sellafield. Today’s nuclear site covers the area that was once known as Low Sellafield.

The site was chosen as a TNT production plant during World War II because of its remote location. It was simply too far west for German bombers to reach.

The UK’s atomic weapons programme

As Britain celebrated the end of World War II, new tensions occupied the political agenda. Foremost was the increasing tension between east and west, known as the Cold War.

Sellafield’s support of the atomic weapons programme that followed created a nuclear legacy that makes up some of the most hazardous work done on the site today.

A nuclear deterrent

Atomic weapons were seen as the best deterrent to a third world war. Britain had been exploring their use and worked with American scientists in the Manhattan Project.

Although successful, the collaboration was brought to an end with the signing of the McMahon Act in the US Congress. The McMahon Act prohibited America from sharing atomic secrets with other countries.

Britain’s Prime Minister, Clement Atlee, created the country’s atomic programme and chose Sellafield to produce the plutonium needed for the bomb.

Why Sellafield?

The Sellafield site had already been used to support national defence, thanks to its years as a munitions factory during World War II. It also had a strong local workforce, was remote and had a good water supply in the form of the River Calder.

Working at Windscale

Work started on the Sellafield site – which was renamed Windscale – in 1947. It took more than 5,300 construction workers, engineers and architects less than five years to design and build a fully operational nuclear facility.

To put this into context, in the same time that it took to build the Olympic Stadium at the start of the 21st century, the Windscale workforce of the 1940s and 1950s designed and constructed:

- 2 nuclear reactors

- 2 ventilation chimneys (each standing 300m tall) to disperse heat from the reactors

- a reprocessing plant that could take the cooled fuel and produce the plutonium needed for the atomic bomb

- a storage pond that would allow the used nuclear fuel to cool

- a waste silo that would store intermediate level nuclear waste generated by reprocessing

These buildings are better known today as:

- Windscale Reactors 1 and 2

- Windscale Pile Chimney 1 (chimney 2 was demolished in 2001)

- the First Generation Reprocessing Plant

- the Pile Fuel Storage Pond

- the Pile Fuel Cladding Silo

The Windscale fire

During the construction of the Windscale buildings, Chief Engineer, John Cockcroft, had insisted that filters were installed at the top of the chimney stacks.

In October 1957, a fire broke out in Windscale Reactor 1.

It was the filter at the top of Windscale Pile Chimney 1 that stopped the disaster from becoming a catastrophe as it limited the amount of radiation released into the environment.

Cockcroft went on to become a Nobel-winning physicist.

The Windscale fire was a wake-up call for the nuclear industry. It led to the closure of both nuclear reactors at the site and vast operational and technical improvements in nuclear reactor design, technology, licensing and regulation.

Harnessing the power of the atom

While the national defence programme at Sellafield was well underway in the 1950s, homes across the country had more electrical appliances than ever before. The demand for affordable electricity had never been higher.

The atomic age

The Windscale reactors that were producing plutonium were generating a significant amount of heat that was ultimately lost through the two discharge chimneys.

In 1952, it was agreed that 4 new nuclear reactors would be built at Sellafield, this time capturing the heat that was produced and using it to generate electricity. Construction started the following year.

World firsts

The world’s first commercial-sized nuclear power station, Calder Hall, was opened in 1956 by HM Queen Elizabeth II. Calder Hall provided the UK with electricity for 47 years until it closed in 2003, but its legacy doesn’t stop there. The design of the station was replicated, creating a fleet of 24 nuclear reactors across the country.

On the other side of the Sellafield site, a third reactor design was being developed. The Windscale Advanced Gas-cooled Reactor, which became the forerunner to the UK’s 14 AGR reactors.

Can you recycle nuclear fuel?

Unlike coal, oil and gas, nuclear fuel can be re-used. It was a process called ‘reprocessing’ that the teams at Sellafield used to extract plutonium for atomic weapons in the site’s earliest operations.

During the late 1950s and early 1960s, the teams designed and built a new reprocessing building that would be able to separate uranium and plutonium from fuel that was being used in the new Magnox stations, like Calder Hall.

To do this work the site also needed another storage pond to cool the fuel before it was reprocessed, and a waste silo to store the fuel’s outer cladding. This added the following buildings to the Sellafield site:

- Magnox Reprocessing Plant

- First Generation Magnox Storage Pond

- Magnox Swarf Storage Silo

- the Fuel Handling Plant (built to replace the First Generation Magnox Storage Pond)

Thorp

In the 1980s and 1990s, the teams at Sellafield designed and built a new reprocessing facility on the site. The Thermal Oxide Reprocessing Plant – or Thorp as it is better known – could recycle oxide fuel from UK and overseas customers, generating significant revenue for the UK, and it could do it all under one roof.

The construction of Thorp pulled almost 5,000 contractors to the site. Stretching over a third of a mile, Thorp is still the single largest building at Sellafield.

By 2011, Thorp had dispatched more than 1,200 tonnes of uranium for customers to recycle into new fuel, saving more than 14 million tonnes of CO2 from fossil fuel generation.

Nuclear waste – separating fact from fiction

Many facets of the nuclear industry cause debate, but none capture the interest and emotion more than the issue of nuclear waste.

What exactly is nuclear waste, what does it look like, where is it and where will it end up?

Popular culture has created an idea of what nuclear waste is and how it behaves. Films and cartoons have conjured an image of a liquid sludge that glows in the dark and destroys everything in its wake. It evokes fear and a lack of control.

The reality is that a small percentage of the nuclear waste generated at Sellafield is liquid. And even then our processes are designed to convert it into a solid stable form.

Other waste items are mixed with concrete inside drums to contain it as a solid mass.

By far the largest quantity of nuclear waste is far more recognisable and mundane, and only half of it is generated by the nuclear industry.

What is low level nuclear waste?

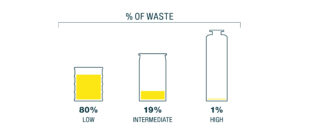

Low level waste accounts for 80% of all nuclear waste and is only slightly radioactive. It includes things like gloves, protective clothing, paper towels, metal and concrete.

It also includes clothing and items used by doctors and nurses during medical procedures like x-rays, and by researchers in laboratories across the country.

We have invested heavily in recycling and treatment options so that we can reduce the amount of low level waste that is sent to the national Low Level Waste Repository.

What is intermediate level nuclear waste?

Intermediate level nuclear waste includes materials such as fuel element cladding, contaminated equipment, and plutonium contaminated materials.

It is chopped up, mixed with a special grout inside high-integrity stainless steel drums, and stored in engineered stores.

What is high level nuclear waste?

Highly active liquid waste is a by-product of reprocessing used nuclear fuel. It is ‘vitrified’, meaning it is dried to a powder and mixed with glass at a temperature of around 1,200 degrees Celsius.

The molten mixture is then poured into stainless steel containers and allowed to solidify. We store the waste in a specially engineered store, pending its final disposal in the UK, or return it to its country of origin.

Guardians of special nuclear materials

The nature of our work at Sellafield means that one of our core capabilities is the ability to manage and store special nuclear materials safely.

For security reasons we don’t show how or where these nuclear materials are stored, but our regulators closely monitor the activity.

Environmental clean-up has gone nuclear

Sellafield has been more than seven decades in the making. Each chapter of the site’s history delivered great benefit for the country while creating a complex nuclear clean-up challenge for which there are no blueprints.

Opportunities for excellence

We can’t clean up the site on our own.

Our teams work hand-in-hand with colleagues from the supply chain. We spend more than half of our annual £2 billion budget bringing in specialists in nuclear, engineering, construction and demolition.

And behind the people working to remove nuclear hazards is an army of people looking for a better, safer, more efficient way to get the job done. They’re in laboratories, classrooms, offices and factories across the country, spending more than £80 million every year on research and development.

Cleaning up the site will take us more than 100 years, and there is much that we still don’t know. Every day we are building greater certainty, and we will be the generation that makes demonstrable progress in cleaning up the site.

That will be our legacy.

2 comments

Comment by P Edant posted on

Spelling error paragraph 2 - COASTAL should have 2 As in it. Thanks

Comment by sarahcorlett posted on

Thanks P Edant, I will correct that now.

Sellafield Ltd