Before we were Sellafield, we were Windscale. A small collection of buildings (two reactors – known as piles, two chimneys, one fuel cooling pond, one waste storage silo, and a reprocessing plant) designed to help the UK develop a nuclear deterrent that would sit at the heart of the country’s national defence.

Designing and building those ground-breaking nuclear facilities made the site the birthplace of the country’s civil nuclear industry. It also meant that the people working there were true nuclear pioneers.

That pioneering spirit continues, but today our brilliant people and supply chain partners have a different challenge – how do we safely decommission these legacy facilities? And how can we do it in such a way that others can learn and benefit from our work?

The origins of Windscale

After the Second World War, fears of a third led nations to pursue nuclear weapons as deterrents. Britain, initially part of the Manhattan Project, had to develop its own capability after the U.S. passed the McMahon Act, ending atomic collaboration.

Sellafield, formerly a munitions factory, was chosen to produce plutonium for the weapon. In 1947, the government approved the construction of two Windscale pile reactors.

Just three years later, in 1950, the first reactor started working and by 1952 had produced the first batch of metallic plutonium.

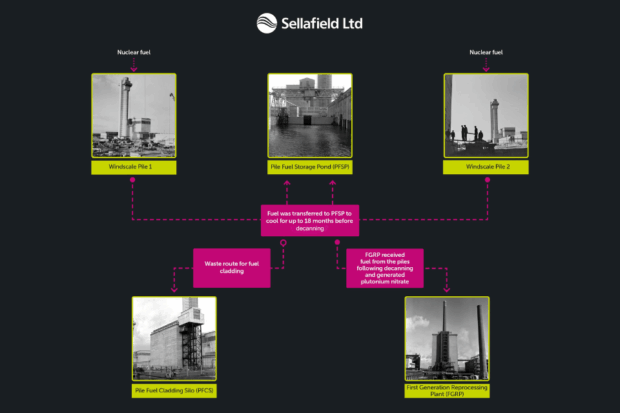

To do this, the teams on site had to design and build support buildings, including

- the Pile Fuel Storage Pond which would cool the fuel when it came out of the reactor,

- the First-Generation Reprocessing Plant to separate the Plutonium from the Uranium and waste products in the used fuel before going on for further processing, and

- the Pile Fuel Cladding Silo to store the outer casings of the used fuel rods.

Both of the reactors were permanently shut down in 1957 following a fire in reactor 1.

Some of the Windscale buildings were repurposed after the fire.

Windscale Pile Reactors

Constructed between 1946 and 1951, Pile 1 and Pile 2 were among the site’s earliest buildings. Both reactors were shut down following the 1957 fire that occurred in the reactor of Pile 1.

Purpose of the Windscale Piles

The two reactors were the first stage in the process of production of material for the UK’s defence programme via neutron irradiation of natural uranium. Fuel was loaded into the reactor and discharged into a water duct.

Windscale Piles decommissioning progress

The fire in Pile 1 caused damage to both the reactor and the chimney. This has made the decommissioning of this facility more complex than its Pile 2 counterpart.

Pile 1

- Chimney: The diffuser and filter galleries were removed using a 162-metre crane and diamond wire cutting. Famously, this bulky filtration system was a last-minute addition, placed unusually at its summit. Despite being mockingly referred to as ‘Cockroft’s Folly’, after its designer Sir John Cockroft, it turned out to be a masterstroke. When the fire broke out, the sky-high filters captured an estimated 95 per cent of the radioactive dust created. We are now focussing on dismantling the chimney barrel. This will be done by using a Suspended Platform with Incremental Descent developed by ADAPT (better known as SPIDA) - a suspended hydraulic platform currently being tested off-site.

- Reactor: Due to the fire, some fuel remains trapped in fire-damaged channels, inaccessible using original discharge equipment. We are currently testing and developing methods to safely retrieve it.

Pile 2

- The reactor was defueled as per standard operations.

- The chimney filter was removed, its height was reduced and the chimney was capped in the 1990s.

- By decommissioning this chimney first, we have been able to apply learning to the dismantling of the chimney from Pile 1.

- Over the past 4 years we have been preparing Pile 2’s facilities for remediation as we continue to dismantle the buildings to a safe and secure end state.

Pile Fuel Storage Pond

Built between 1948–1952, the Pile Fuel Storage Pond is the world’s largest open-air nuclear fuel storage pond.

Purpose of the Pile Fuel Storage Pond

The pond was originally designed to cool, decan, and prepare spent fuel from the Windscale Piles before reprocessing. It was later adapted and handled fuel from other reactor types. Whilst operational, the Pile Fuel Storage Pond accumulated a mix of fuel, isotopes, debris, and sludge.

Pile Fuel Storage Pond decommissioning progress

- The facility was refurbished to in the 1980s with modern systems.

- This allowed waste retrievals to begin in the 1990s.

- By 2016, 70% of radioactivity had been removed.

- We are now in the final phase of retrievals. Current efforts focus on consolidating remaining material using innovation lead methods such as remotely operated vehicles and a fully submersible micro-digger.

- Final steps in decommissioning include floor clearance, dewatering, and demolition.

Read more about the Pile Fuel Storage Pond

First-Generation Reprocessing Plant

Originally known as the Primary Separation Plant, the First-Generation Reprocessing Plant was built in the late 1940s. It featured six process cells and a 61-metre ventilation stack.

Purpose of the First-Generation Reprocessing Plant

The plant received spent fuel from the Pile Fuel Storage Pond and carried out the first stage of reprocessing for material from the Windscale Pile reactors. The separated materials were then transferred to other facilities for further processing.

The plant operated successfully for 12 years before reprocessing responsibilities shifted to the Magnox Reprocessing Plant. Between 1968 and 1973, part of the facility was refurbished to experimentally dismantle and dissolve oxide fuel from reactors like Windscale Advanced Gas Reactor (WAGR), demonstrating the feasibility of oxide fuel reprocessing.

Until its stack was removed, the reprocessing plant also provided ventilation to neighbouring operational facilities.

First Generation Reprocessing Plant decommissioning progress

The plant has been partially decommissioned, with ongoing monitoring and maintenance to ensure safety and prevent infrastructure degradation.

Ventilation stack

- The original 61-metre stack was safely dismantled in 2019 due to its age and height.

- Prior to demolition, the Separation Area Ventilation stack was constructed and became operational in April 2016, ensuring continued ventilation for dependent facilities.

- The old stack was removed top-down using a self-climbing platform.

Redundant cells

Innovative techniques have been applied to maintain safety and structural integrity:

- Aerated Grout Stabilisation: In one cell, acidic vapours had corroded steel structures. A lightweight aerated grout was injected to stabilise the area without adding excessive weight. This grout can be deflated to one-third its size during demolition, easing removal.

- Sugar-Based Fogging: In another cell, airborne contamination was reduced by spraying a fine sugar mist. This settled as a surface coating, significantly lowering airborne hazards.

Read more about the First Generation Reprocessing Plant

Pile Fuel Cladding Silo

Constructed in the 1950s, the Pile Fuel Cladding Silo was inspired by North American grain silos.

Purpose of the Pile Fuel Cladding Silo

The silo was a dry storage-facility that received and stored cladding from decanned fuel. It also held other intermediate-level waste from early site operations.

It contains six large compartments and was not originally designed for waste retrieval.

Pile Fuel Cladding Silo decommissioning progress

- A superstructure was built in 2012 to enable safe access.

- Giant, 12-tonne steel doors were installed on each compartment.

- In 2017, access holes were cut into the silo’s top.

- We designed, manufactured, tested and installed 9 huge modules containing the remotely operated retrievals machinery needed to grab the waste and empty the silo.

- After making the first retrievals in 2023, we are now ramping up retrievals efforts to empty the silo.

Recent Comments