Today marks the 62nd anniversary of the UK's worst ever nuclear disaster. As time moves forward, so does the project to decommission the pile chimney.

The two 125 metre tall ventilation chimneys were built during the early days of the country’s atomic age. Their iconic image was cemented by nuclear pioneer and Windscale Chief Engineer John Cockcroft. He insisted that filters be added to the chimneys.

As construction was well under way at this point, the filters were installed to the top of the structures, giving them their unique shape.

The filter galleries proved their value with the fire in Windscale reactor 1 in 1957. It was these filters that prevented this disaster from becoming a catastrophe, by limiting the amount of radiation released into the environment.

Following the fire, both reactors were closed, and the chimneys were no longer needed. The second chimney was demolished in 2001. However, the contamination from the fire made the challenge of removing chimney 1 much more significant.

Given we’re now 62 years on from the fire, the chimney’s useful life has long since departed. The condition of the stack – which no longer meets modern structural standards – means that its demolition is now a priority. The passage of time, along with more advanced assessment and decommissioning techniques means this is now happening.

The first decommissioning work started in the 1980s with the removal of some of the brick and ancillary facilities. Work stopped in 2003 following a fatality during work inside the chimney.

Decommissioning restarted in 2014 with the opening up of the structure. This was followed by the removal of the now-legendary filter galleries at the top of the stack.

Progress

Since that point, work has been focused on the identification and delivery of a safe means of removing the diffuser from the top of the chimney stack.

Learning from work outside of the Sellafield site led to an approach where we cut the structure into large blocks and transport these to the ground.

To enable this, we had to build a tower crane. This is a familiar site on construction sites and in city centres around the world. But we’d never used one on in such a congested and sensitive area of the Sellafield site.

This meant that much work went into making sure that this was a safe and suitable option for a congested nuclear site. We have worked with supply chain partners, who more familiar with this kind of work.

The team had to overcome challenges relating to logistics and infrastructure, as well as ensuring the crane could be piled into the ground and affixed to the chimney stack to ensure it stays in place.

Following the completion of this work and all appropriate safety checks and assessments, the first block was moved in December 2018.

Since then, progress has been swift, and more than 100 blocks and around 7 metres have been removed from the top of the stack – forever changing the Sellafield skyline.

Each metre of height removed from the stack generates around 100 tonnes of concrete waste. When they’ve been analysed, blocks are transferred to the bagging station where another crane is used to manoeuvre them ready for transport to interim storage.

Following this, they are disposed of, either on the Sellafield site or at the Low Level Waste Repository.

A team effort

The project is a collaboration between ourselves and ADAPT – one of our Decommissioning Delivery Partnership partners.

Kaefer are providing demolition access services with Design Services Alliance providing structural design and validation services.

The project is supported by our own Sellafield Ltd teams from across the organisation.

Employee stories

Despite the fire having taken place so many years ago, a number of Sellafield Ltd employees have stories to share of the event – either from family members or former colleagues.

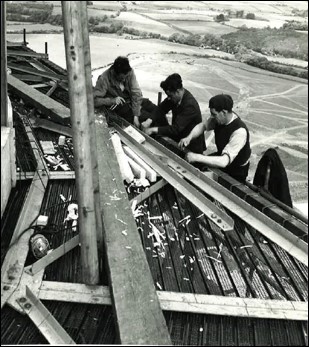

Indeed, pictures from the construction of the piles and the chimneys back in the late 1940s and early 1950s show just how much work on a construction site has changed since those early days of the country’s nuclear industry.

Personal protective equipment was nowhere to be seen, and construction workers had a different risk and hazard perception to the modern age.

1 comment

Comment by R Millington posted on

"... we had to build a tower crane. This is a familiar site on construction sites and in city centres around the world. But we’d never used one on the Sellafield site". This statement is incorrect, there were at least half a dozen tower cranes operating on the site during the construction of the THORP plant.